Introducing Italpresse

Technological innovation, quality and flexibility from this renowned manufacturer of hydraulic presses and lines.Italpresse are renowned manufacturers of a wide range of hydraulic presses and lines complete with pressing intended for serious industry use. Their constant focus on excellence extends through technological innovation, quality and production flexibility. Being founded in 1954, Italpresse offers their customers a strong history of excellence.

At R&J Machinery, we are proud to be a preferred UK supplier and stockist of Italpresse machines, and offer our extensive experience in delivering the perfect machine to you on time, competitively priced, and with a first-class after-sales service.

-

Excellent value for money from these Italian machines

-

Solid steel plattens are available as an option

-

Benefit from the professional backup and service from R&J Machinery

Italpresse Applications

Italpresse hydraulic presses and lines for a variety of industries and processesSelect an application to be fast-tracked to that content.

-

Woodworking

-

LW, Sandwich & Honeycomb Panels

-

Automotive

-

Composites & Solid Surfaces

-

Foamed Panels

-

Special Applications

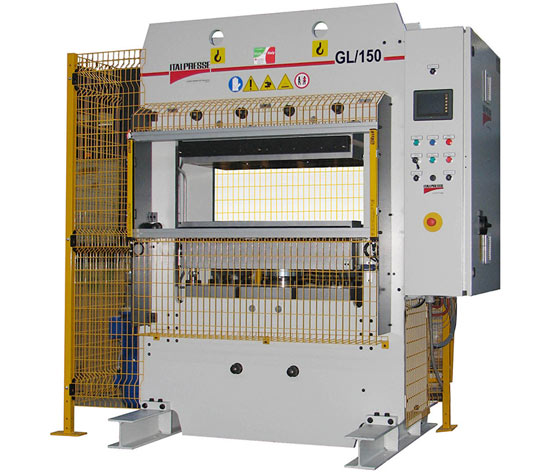

Woodworking Presses

Italpresse technologies and solutions for woodworking.Italpresse a wide range of woodworking presses ranges to cater to the furniture, wooden panels, doors and windows, laminate flooring and wooden build components industries. Their products include:

-

Manual Loading Hot Presses

-

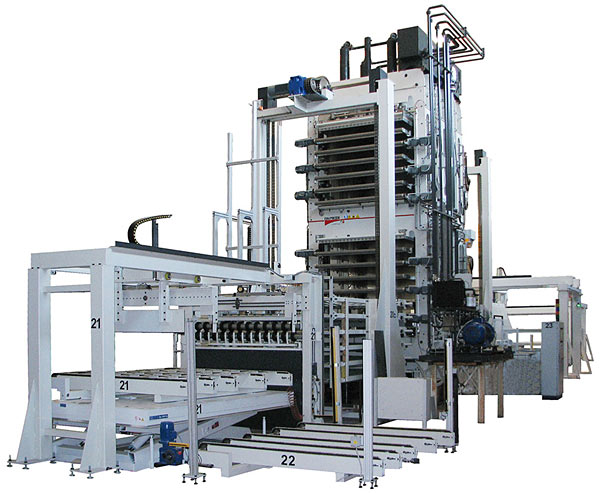

Lines for Panel Lamination (Veneers, Laminates & Papers)

-

Lines for the Production of Panels

-

Lines for Doors

-

Lines for Laminate Flooring

-

Cold Presses

-

3D Membrane Presses

-

Clamps for Doors & Windows and Furniture Bodies

-

Lines for Solid Wood Edge and Face Glueing

-

Presses for Moulding

-

Presses for Bending

-

Automatic Systems, Glueing Systems and Cutters

LW, Sandwich & Honeycomb Panels

Italpresse solutions for a wide range of industriesIn a growing number of sectors, there is an increasing demand for innovative, performative, cheaper materials that better protect the environment and the health of those who use them.

In response, Italpresse offers its solution - specifically developed for the production of composite lightweight panels. Individual elements to integrate pre-existing lines can be provided, or complete production lines.

Italpresse has developed applications in the following industries:

- Furniture (home, office, community, ships, hotels, etc.)

- Doors

- Insulation (acoustic, thermal, cold storage, etc.)

- Automotive sector

- Packaging

- Planes, ships, trains

- Caravans

- Floating floors

- Construction

- False ceilings

- Display units and shelves

- Exhibition stands

- Advertising boards

- Defence industry

For the middle layer (core) cardboard, aluminium, Nomex®, polypropylene, polycarbonate, etc. honeycomb can be used or lightweight chipboard or MDF, cork, balsa, foam panels or agglomerates.

For the coatings (skins) MDF, plywood, other wood-based materials, aluminium, steel, laminates, etc. can be used.

Automotive Presses & Production Systems

Solutions for external and internal automotive componentsThanks to well-established long-term partnerships with some of the major companies in the automotive industry, Italpresse has developed a unique know-how in this sector.

Italpresse are particularly specialised in the production of presses and systems for the production of internal and external components and thermal and acoustic insulation systems for cars and industrial vehicles. Hundreds of their systems all over the world produce internal and external components such as instrument panels, steering wheels, central tunnels, internal door panels, carpeting, wheel housing, luggage compartments, side boot covers, headliners and pillars, seat backs, thermal and acoustic insulating panels and composite exterior body panels.

Their production program currently includes presses and systems for moulding, forming, punching and rolling with the possibility to load and unload the pieces and change the mould with various degrees of automation.

Italpresse can also provide advanced heating and cooling systems for cold, hot or cold/hot cycles.

Composites & Solid Surfaces

Italpresse systems for composite processingComposite materials are required by the industries where it is necessary to meet requirements of low weight and high mechanical characteristics, in particular: aerospace, aviation, automotive, marine, mass transportation, sport, defence, energy, construction, furniture.

With Italpresse systems, the main reinforcement fibres (glass, carbon, aramid fibres) and polymer matrices based on thermosetting resins (polyester, phenolic, epoxy, polyamide resins) or thermoplastic resins can be processed.

Italpresse manufactures complete presses and systems for different production processes for the production of composite materials: Compression Moulding, Injection Moulding, Resin Transfer Moulding and thermoforming.

They also offer customised systems with specific pressures from 1 to 300 Kg/Cm2, temperatures up to 500°C and, where required, the hot/cold cycle.

Foamed Panels

Solutions for various industriesItalpresse produces a complete range of presses and systems for the discontinuous production of foamed panels for injection into a closed mould or casting into an open mould and for the bonding of sandwich panels with a core made of polyurethane and other high and low density foamed materials.

The considerable expertise accumulated over the years allows Italpresse to offer complete and reliable solutions at different levels of productivity in the following industries:

- The refrigeration industry (refrigeration and air conditioning systems, cold storage rooms, display cases and refrigerator aisles)

- Thermal insulation for construction (walls, floors, roofs)

- Acoustic and thermo-acoustic insulation

- Refrigerated and insulated trucks

- Doors and insulated doors

- The automotive industry

- The mass transportation industry (train, underground, bus)

- The marine industry

- The aviation industry

- The defence industry (ballistic panels, shelters)

- The production of panels recycled from polyurethane waste

- The caravan and RV industry, sandwich panels for various applications

Special Applications

Italpresse design and complete systems for special and custom applicationsItalpresse have gained significant experience in the field of recycling materials (wood, rubber, polyurethane, glass, cork, etc...) to achieve panels starting from machining scraps.

Other sectors where Italpresse's expertise reaches include systems for the production of fibre cement panels, systems for the production of panels for acoustic and thermo-acoustic insulation, systems for the production of slabs made of cellulose acetate with hot-cold cycle, presses for gaskets, presses for laboratories.

Used Italpresse Machines

Fully prepared, serviced and quality-checked.The following used Italpresse machines are currently available from R&J Machinery. Each machine is prepared to the highest standard by our engineers, and comes with service history and full usage data. Why not visit our showroom to view these used woodwork machines in operation first-hand?

We are a UK Italpresse Agent

R&J Machinery has an extensive working partnership with Italpresse, and we are proud to be a main agent for their machines and spare parts in the United Kingdom.

You can be sure that our team are fully qualified to offer you guidance on the Italpresse machine you require, and fully qualified to service and maintain your existing machines to the highest standard. We look forward to talking to you soon about the stunning range of Italpresse machines!