Introducing the Osama MIXER CLT-A

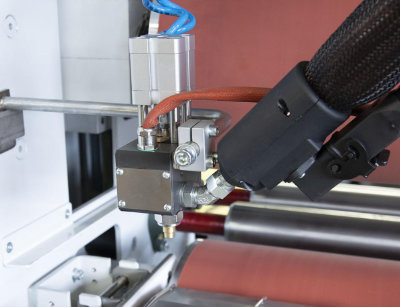

Automatic mixing and feeding system of two-components vinyl and urea glues with catalysers, sulphate and isocyanate, for rollers gluing machine.Standard version includes a mixing head mounted on the gluing machine, fed by special pumps for glue and catalyser. The pumps take the products directly form the storage tanks and they are activated by the level sensors placed between the rollers, thereby ensuring a constant level of glue.

The feeding process is set by a PLC touch screen placed on the control cabinet, where it is also possible to select the feeding of the upper rollers, the lower rollers, or both at the same time.

Osama Servicing

Osama machines are only as good as their preparation. Our in-house team of trained engineers are on-hand to visit your workshop and provide you with scheduled Osama servicing, ensuring that your machines are optimised for maximum performance and continue to meet safety standards.

R&J Machinery is proud to be one of the main UK agents for Osama Technologies

R&J Machinery has a long relationship with Osama, and we are proud to be the main UK agents and importers for their machines and spare parts. We are one of the top-tier suppliers of Osama glueing technologies across Europe, and our team of service and repair engineers travels to Osama in Italy for training on the latest machinery developments.

You can be sure that our team are fully qualified to offer you guidance on the ideal Osama roller system for you, and are fully qualified to service and maintain your existing machines to the highest standard. We look forward to talking to you soon about all things Osama!

For sales, servicing, parts, advice and support, please call our office team on 01455 840224.

Like the Osama MIXER CLT-A? Book a Demo!

Test-drive our machinery in our 16,000 sq ft facilityOur machines are ready for your inspection and testing at short notice in a purpose-built environment. Why not visit us at our location in Leicestershire to compare and contrast similar machines, and have our experts show you the key differences between models and brands?

Request Osama Servicing Information

R&J Machinery's in-house team of trained engineers are on-hand to visit your workshop and provide you with scheduled Osama servicing. To request more information about the servicing packages we offer, please speak to our knowledgeable team on 01455 840224 or complete this enquiry form.